Industrial Belts

Industrial Belt Solutions

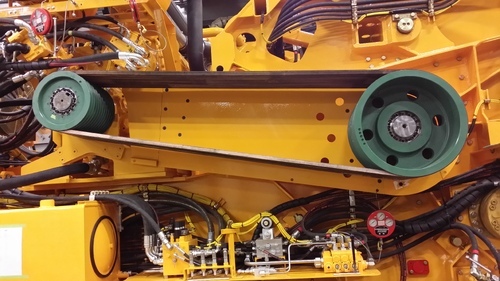

Ready for Heavy-Duty Use

Mitsuboshi delivers high-performance industrial power transmission belts designed to meet the rigorous demands of OEMs and end users alike. Our innovative product lineup includes synchronous belts, frictional drive belts, and direct coupling solutions—all engineered for maximum durability, efficiency, and reliability in tough environments. From factory automation and construction equipment to crushing units and cement mills, MBL belts are built to power your machinery with superior performance and minimal downtime.

Industrial Belt Applications

Forestry

Classical wrapped and raw-edge cogged V-belts drive sawmills, chippers, and debarkers—offering high shock-load resistance in harsh, debris-filled environments.

Mining

Heavy-duty timing belts and banded V-belts power crushers, conveyors, and ventilation systems—built to handle abrasion, vibration, and extreme load demands.

Oil & Gas Fields

Classical V-belts and narrow wedge V-belts operate pump jacks and drilling rigs, delivering high torque and temperature stability in remote, rugged conditions.

Renewable Energy

Synchronous belts ensure efficient, low-maintenance power transmission in wind turbines, hydro generators, and auxiliary equipment.

Cement & Aggregate

Banded V-belts and polyurethane V-belts run crushers, rotary kilns, and mixers—designed for continuous operation in dusty, high-vibration environments.

Food & Beverage Processing

Friction-driven flat belts and polyurethane timing belts power conveyors and mixers with smooth, sanitary motion for cleanroom-ready applications.

Factory Automation

High-precision timing belts and polyurethane belts drive robotic arms, conveyors, and indexing equipment, offering low noise, minimal backlash, and tight tolerances.

HVAC Systems

Classical V-belts and variable speed belts power fans, blowers, and compressors in commercial HVAC systems, balancing quiet operation with energy efficiency.

Pulp & Paper Mills

Raw-edge V-belts and timing belts drive paper machines, dryers, and rollers—built for high-speed operation, humidity resistance, and continuous uptime.

Products for Industrial Applications

Synchronous

Synchronous power transmission belts, also known as timing belts, feature teeth on the inner surface that engage with grooves on the pulleys, providing precise and slip-free power transmission. They are commonly used in applications requiring accurate timing and positioning, such as robotics, printing presses, CNC machines, and automotive engines. These belts are made from materials like rubber and reinforced with fibers for added strength. They offer precise motion control, require low maintenance, and are efficient in power transmission. However, proper alignment is crucial, and they may not be suitable for applications with high shock loads or extreme flexing requirements.

Frictional-Forced

Frictional-forced power transmission belts are essential in machinery, transferring power between rotating shafts. Made from durable rubber or synthetic polymers, they’re widely used in conveyors, HVAC systems, and agricultural equipment. With excellent flexibility and precise design, they ensure seamless energy transfer, boosting productivity and operational efficiency. Trusted to withstand friction, tension, and heavy loads, they deliver reliable power in demanding environments. Their adaptability suits a wide range of equipment. As a backbone of industrial systems, they continue evolving to meet the ever-changing demands of modern industry with exceptional performance and reliability.

Direct Connected

Direct-connected power transmission couplings directly connect two shafts to transmit power without intermediary components. They provide a solid link between driving and driven shafts. There are two types: rigid and flexible. Rigid couplings have no relative motion or misalignment, while flexible couplings accommodate misalignments and reduce shock and vibration. Used in various industrial applications for reliable power transfer, they offer high efficiency, simple design, and precise transmission. Proper alignment is crucial, so choose the appropriate coupling based on torque, speed, misalignment tolerance, and environmental conditions.